Share

Functional Foam-Control – How to tailor foam levels to enhance product perception and cleaning performance

Author

Ashish Taneja, Lab Leader-Home and Industrial & Institutional CleaningPublished On

November 18, 2019Author

Ashish Taneja, Lab Leader-Home and Industrial & Institutional CleaningPublished On

November 18, 2019Share

Markets

- Institutional Cleaning & Sanitation

Related Products

Staying in control of the type and amount of foam created by your formulation gives you the power to tailor your products to the needs of a specific task or environment.

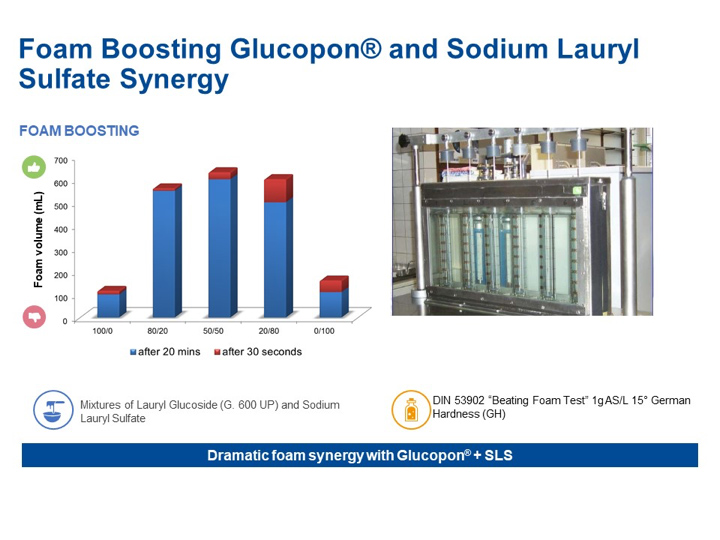

Combining Glucopon® and Sodium Lauryl Sulfate (SLS) for Superior Foam

For hard surface cleaning, when you want a high and stable foam, sodium lauryl sulfate (SLS) is a good starting point with suitable foam production; however, it is also known as a skin irritant with a foam quality that is negatively impacted by hard water.

Glucopon® 600 UP is a milder surfactant that is 100% bio-based, reduces skin irritation synergistically, and is unaffected by water hardness.

When seeking out the optimal ratio of Glucopon to SLS in a formulation, BASF measured the height of the resulting foam using the beating foam test to measure the stability of the foam. As illustrated, when comparing foam levels after 30 seconds and 20 minutes, the 50:50 ratio of SLS to Glucopon produced the highest and most stable foam.

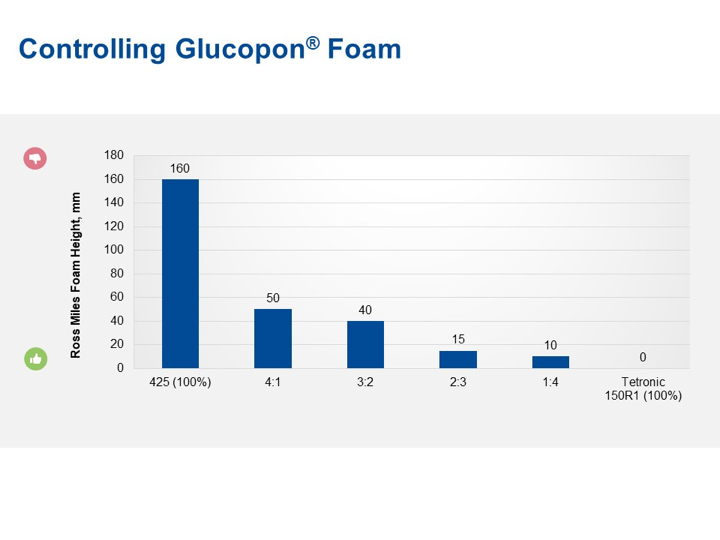

Controling Foam with Tetronic® 150R1

There are times when the cleaning efficacy of Glucopon is desired, but the foam is not. Too much foam can be difficult to rinse and can leave a residue. It is also possible for key active ingredients to get stuck in the lamina of the foam and lose their effectiveness.

Tetronic® 150R1 is a surfactant that can be used to control foam levels. As shown, when comparing foam produced at various ratios, the height of the foam using the Ross-Miles test drops as the ratio of Tetronic 150R1 to Glucopon is increased.